Common symptoms and analysis of concrete mixing plant

Jun 14, 2016

One, Belt wet slip

Symptoms:

On a rainy, inclined belt slipping when the load operation.

Analysis:

Rain, moisture in the aggregates and exposed parts of the belt easy to wet belt wet especially in the wet, reducing the coefficient of friction between belt and drive pulley so that the drum twist torch passed to a belt reduction, when the moment is less than the torque required for belt material handling, the belt appeared to slip.

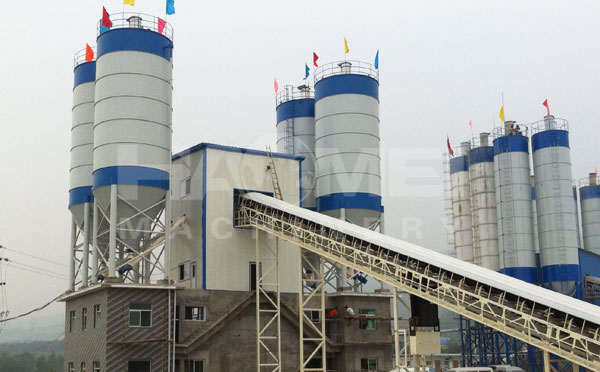

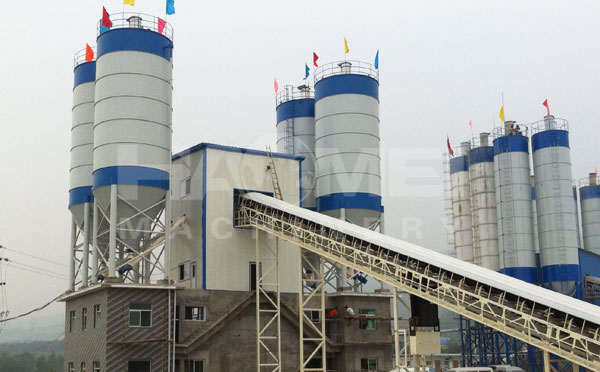

Concrete batching plant process:

1, increase the belt tensioning device with heavy or tensioning the belt adjusting screw increase pressure between belt and drum, thus driving drum and friction between the belt.

2, around drive pulley tensioner rollers, increasing the angle of the belt on the drive pulley, increasing friction.

3, cutting straight grooves in the drive roller rubber coating layer, increasing the coefficient of friction.

4, top 3 does not resolve, you need replacement of the sliding rollers.

Second, additive pumps up

Symptoms:

Admixture admixture on the pump when the pump is not.

Analysis:

1, additives there are air bubbles in the pump.

2, admixtures box material deficiencies.

3, additive concrete pump impeller is damaged.

Process:

1, open the admixtures vent screws remove admixture in the bubble.

2, box add to admixture admixture.

3, check the impeller of admixtures, replacement parts, as appropriate.

Three belt damage

Symptoms:

After the end of use, belt surface of degumming, cracks, scratches, and so on.

Analysis: metal belt cleaner does not adjust, easy to damage the belt, causing surface rubber belt fell off. Cleaning is not properly installed, sharp gravel stuck between cleaner can damage the belt. Belt itself poor quality, prone to these defects.

Process:

Belt in the event of degumming, cracks, scratches and other defects should be repaired. When the belt when injury occurs, the first thing to address the factors of belt damage, such as Sweeper damage, you need to immediately adjust or replace the cleaner, and then repair belt. Belt damage is very small, available on-site repair belt repair glue. When when the belt damaged or partially damaged, local damage belt can be removed, the replacement of a belt, bond with sulfide. Belt damage not processed in a timely manner, spread the belt when injury, there is no fixed value, can only be replaced in its entirety.

Four uneven, aggregate belt conveyor

Symptoms:

Aggregate item on the unloaded belt has piled up, causing belt bulk, or aggregate vacancy on the conveyor belt, causing gravel bulk material.

Analysis:

Batching multiple unloading of aggregates to the belt on the sequence and time interval can be adjusted arbitrarily. General discharge order final unloading of aggregates of sand, unloading time interval required for the former aggregate fell at the end of the belt with an aggregate fall onto the belt of the head coincide. If the interval is too short, it is the aggregate of the former and the latter aggregate overlapping stack, stack will cause too much bulk, if the interval is too large between the two aggregate vacancy before an item if it is gravel, then roll in the belt and hoop.

Process:

1, adjust the aggregate discharge order, guarantee the sand for the last discharge.

2, according to the distribution of aggregate belt adjust the discharge interval of various aggregates to ensure continuous and uniform material distribution belt. Time intervals are usually required adjustments.

(Chat Online)

(Chat Online)