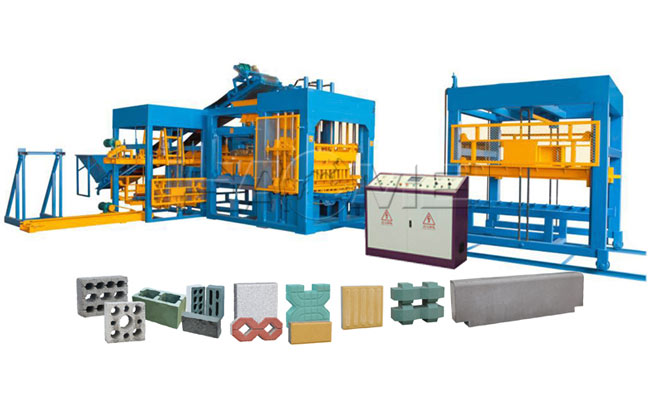

Types of Paving Bricks Making Machine

Jun 10, 2025

Paving brick making machine is a kind of mechanical equipment specially used for producing various types of paving bricks (such as concrete bricks, colored bricks, permeable bricks, etc.). This equipment is widely used in the fields of construction, gardening, road construction, etc.

Working principle of paving bricks machine:

- Raw material mixing principle:

Fully mix materials such as construction waste, stone powder, sand, fly ash, waste ceramsite slag, smelting slag, etc. with a small amount of cement. These raw materials are evenly mixed in the mixer through the rotating motion of the mixing blades to provide suitable blanks for subsequent brick making.

- Forming principle:

The mixed blanks are fed into the mold, and pressure is applied by the hydraulic power system to compact and form the blanks in the mold. For example, the hydraulic paving brick machine pushes the pressure head through the hydraulic cylinder to statically press the material in the mold, so that the material particles squeeze and fill each other to form a paving brick blank with a certain shape and size.

- Vibration principle:

Some paving brick making machines are also equipped with a vibration device to generate vibration during the pressing process. The vibration can discharge the air in the material, and at the same time make the material particles more closely arranged, thereby improving the density and strength of the brick body.

Types of paving bricks making machine including:

1. Hydraulic paving brick machine:

With hydraulic system as power source, it has the characteristics of high pressure and good molding effect. It can produce paving bricks of various specifications and shapes, and is widely used in paving in urban roads, squares, parking lots and other places.

2. Pavement paving brick machine:

Mainly used to produce various pavement bricks, such as permeable bricks, anti-slip bricks, etc. Some pavement paving brick machines use advanced technologies, such as secondary feeding system, which can produce colorful and multi-layered pavement bricks to meet different pavement paving needs.

3. Curbstone machine:

Specially used for the production of curbstones, its mold and molding process are different from ordinary paving brick machines. The curbstones produced by the curbstone machine have high dimensional accuracy and high strength, which can effectively separate lanes and sidewalks, ensuring the traffic safety and beauty of the road.

4. Color brick machine:

It can produce paving bricks of various colors. By adding different colors of pigments to the raw materials or using special feeding technology, the surface of the brick body presents rich and diverse colors, which enhances the beauty of the road surface.

5. Pattern brick machine:

It can produce paving bricks with patterns or designs. By changing the mold or using a special pressing process, various exquisite patterns can be formed on the surface of the brick, such as imitation stone pattern, imitation antique pattern, etc., which are often used for paving in places such as garden landscapes and pedestrian streets.

Features of paving bricks making machine:

- High production efficiency:

Modern paving brick manufacturing machines use an automated control system to achieve continuous production, greatly improving production efficiency. For example, some large fully automatic paving brick machines can produce thousands of paving bricks per hour.

- Good product quality:

Through precise mold design and hydraulic pressing systems, the paving bricks produced have high dimensional accuracy, high strength, and a smooth surface. At the same time, the application of vibration devices improves the density of the brick body and enhances the wear resistance and penetration resistance of the bricks.

- Energy saving and environmental protection:

Using construction waste, industrial waste residues, etc. as the main raw materials, the recycling of resources is realized, the exploitation of natural raw materials is reduced, the production cost is reduced, and it is also beneficial to environmental protection. In addition, some paving brick manufacturing machines use energy-saving motors and hydraulic systems to reduce energy consumption.

- Easy to operate:

Equipped with a user-friendly operation interface and control system, operators only need simple training to master the operation method. The equipment has functions such as automatic feeding, automatic pressing, and automatic demoulding, which reduces the tediousness of manual operation and reduces labor intensity.

- One machine for multiple uses:

Many paving brick manufacturing machines can produce paving bricks of different specifications, shapes and types by replacing molds, such as permeable bricks, grass bricks, hollow bricks, etc., which meet the needs of different projects and improve the utilization rate of equipment.

Application areas of paving bricks making machine:

- Municipal road construction:

Used for paving sidewalks, non-motorized vehicle lanes, squares, parks and other places of urban roads, providing a comfortable and safe traffic environment, while beautifying the urban landscape.

- Residential community construction:

Can be used for paving roads, parking lots, garden paths and other areas within the community to create a beautiful and pleasant living environment.

- Commercial plaza construction:

Suitable for ground paving in commercial plazas, able to withstand large traffic and vehicle traffic, while showing the characteristics and style of commercial areas.

- Industrial park construction:

Used for the construction of roads, parking lots and other facilities in industrial parks to meet the needs of industrial production and logistics transportation.

- Construction of tourist attractions:

In tourist attractions, various special paving bricks produced by paving brick making machines can be used to pave sightseeing trails, viewing platforms, etc., integrating with the natural landscape to enhance the overall quality of the scenic area.

(Chat Online)

(Chat Online)